This world famous beer is brewed in Czech micro-breweries for more than 150 years in still the same traditional way that is significantly different from the production of beer in industrial breweries. Such beer is also produced in many micro-breweries in Slovakia, because the Czech Republic and Slovakia were a common state where brewers from both countries studied together at same universities and shared brewing skills.

The main difference in the brewing process of Czech beer includes primarily the production of the first intermediate beer product – called wort – by decoction method. This is a traditional Czech technology when part of the wort is pumped into another container and boiled separately. This requires special designed brewhouse that is typical for Czech and Slovak breweries.

The second difference is the main fermentation method. While in the majority of industrial breweries closed pressure vessels – cylindrical-conical tanks – are used for the main fermentation, in the Czech and Slovak Republic open fermentation vats are used most often. Thanks to this method we can during the excursion to the Czech and Slovak micro-breweries experience a wonderful view at fermenting beer, which is creating a foam of various colours and shapes.

Despite these facts even in these traditional countries new interesting innovations and solutions ensuring effectiveness and higher quality are developed. Such technical developments can be applicable in micro-breweries all around the world. Here are couple of solutions that can be seen while visiting Czech and Slovak micro-breweries.

1-st solution – BREWORX VARIO CCT

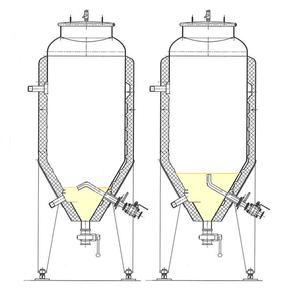

Reduction of beer loss, cost of sanitizing solutions, energy and labour costs during fermentation process of beer in cylindrical-conical fermentation tanks.

An adjustable racking valve system for easy separation of the yeasts from the product (beer, cider, wine …) in fermentation cylindrical-conical tanks without loss of product residues . This system allows the precise height setting of the outlet pipe suction hole just above the actual level of yeast in the tank.

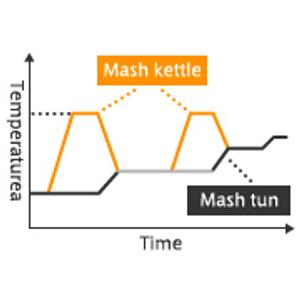

2-nd solution – BREWORX DECOCTION

Modification of current brewhouses to enable production of a traditional Czech beer – reconstructions of infusion brewhouses for the decoction method.

The brewhouse upgrade service includes :

1. The initial consultation and analysis– expert consultation on-site.

2. Project documentation – the technological project documentation includes: technical description and drawings, a detailed description of the technological and technical solutions for the required reconstruction of the brewhouse.

3. The factory equipment production– manufacturing of the required equipment for the reconstruction of the brewhouse according to the project.

4. The technology assembly at place– all manufactured components will be implemented on the existing brewhouse. The brewhouse will be reconstructed according to the project.

5. Commissioning of the production system–completing all operations that are necessary for putting the brewhouse into operation. These works are led by an expert on an installed technology (engineer, brewmaster).

6. Trial operation, operator training – a Czech brewmaster prepares one or more batches of wort in the brewhouse and he instruct the customer how to operate new technology.

3-rd solution – BREWORX MOBILE CIP

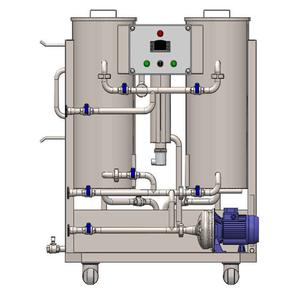

Obligatory equipment in every brewery. The function of CIP station is to perfectly clean, sanitize and disinfect all vessels and piping. Without regular maintenance of all equipment brewery is not possible to produce quality beverages.

Its function is based on circulation of an alkaline or acid solution through a sanitary shower spraying it onto vessel walls and into its space.

It is equipped also with a flow heater with digital temperature regulator ranging from 0°C to 80°C.

The CIP station consists of two main tank for alkaline and acid solution and one vessel for neutralizing of used solutions. The circulation of the sanitizing solutions is provided by an integrated centrifugal pump and system of connecting hoses. Main advantage of such CIP station is the mobility.

4-th solution – BREWORX KEG WASHFILL

Sanitizing and filling of beer kegs using the manual or automatic keg washing & filling machine. The manually or automatically operated keg washer and filler enables washing and filling beer into 5L, 15L, 20L, 30L or 50L kegs. There is possible to fill beer also into plastic kegs (for example Petainers).

The production portfolio of the keg washers and fillers includes simple manual fillers for party kegs or classical beer barrels, semi-automatic machines for rinsing and filling kegs, designed for microbreweries and also powerful keg filling lines for medium breweries which are fully equipped with conveyors, automatic rinsing, sanitizing and filling valves, manipulators and the keg labelling system.

5-th solution – BREWORX MODULO

Complete professional mini brewery by yourself within one day! Without project work, building reconstruction work, expensive costs of installation by team of specialists.

BREWORX MODULO micro-breweries are manufactured according to modern methods from quality stainless steel exclusively from Europe. They enable the production of traditional Czech type beer, but also any other kind of world beer using the decoction or infusion method. Customer can produce light beer, half-dark, dark, stout type beer, ale, pale ale, white beer and many other beer types by Czech and foreign recipes.

Their design also allows the production of bottom and top fermented beers by a modern way of fermentation and maturation in special sealed FUIC units – cylindrical-conical tanks with independent cooling system.

6-th solution – BREWORX BEERCIDERLINE

Extend your brewery’s ability to cider production. For small investment you can get a professional production of beverage which is now conquering the world. The BREWORX BEERCIDERLINE system is designed as optional accessories of small brewery. After upgrade of your brewery you can produce both beer and cider on single production line.

7-th solution – BREWORX FUIC

BREWORX FUIC (Fermentation Unit with Independent Cooler) is a compact unit developed primarily to meet the requirements of micro-breweries which need to test new beers’ recipes. Cylindrical-conical tanks are fully equipped and together with sophisticated cooling system is FUIC ideal to replace the classic self-standing CCTs and storage tanks. Brewery extension and thus increase in the production capacity of the brewery is quick and easy with units FUIC.

Source : Czech Minibreweries s.r.o. : http://www.czechminibreweries.com/

Production portfolio :http://eshop.czechminibreweries.com/