Read in this story:

-How they built the world's first "universal processor"

-What the R&D centre in Bratislava will be responsible for

-Why Danilák decided to build the centre in Slovakia

Ever since he immigrated to the United States, Radoslav Danilák has hoped for a day he could repay Slovakia for the contribution it gave him to succeed abroad.

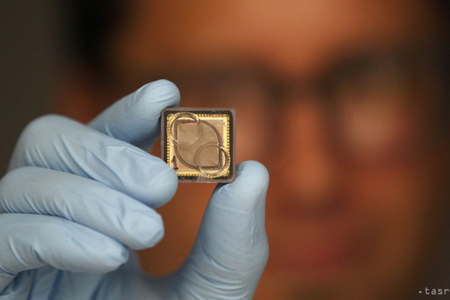

“With Tachyum and Prodigy, that day has finally arrived,” said Danilák, whose Tachyum company has been developing a microprocessor with high performance, low energy consumption and three times cheaper for the operators of data centres compared with the best chip on the market.

In an email interview with The Slovak Spectator, Danilák talks about the developmental stage the project is at and why he decided to place a brand research and development centre in Bratislava.

The Slovak Spectator (TSS): What are the current challenges with the development of chips? What conditions do the new generation chips have to meet?

Radoslav Danilák (RD): In general, challenges to chip design and manufacturing are largely due to the astonishingly small transistor and wire sizes being used in today’s state-of-the-art fabrication plants, such as TSMC in Taiwan.

Today’s chips are built with transistors and wires that are as small as 7nm wide; for comparison the human DNA molecule is 2.5nm wide. At these feature sizes, a host of new problems arise, including quantum effects that must be accounted for in each design. With these absurdly small feature sizes, chip designers today can easily develop chips with up to 10 billion transistors on them. Verifying the functionality of chip designs has also become extremely complicated for the same reasons. Finally, the cost of developing chip products continues to skyrocket, with 7nm mask sets (just the non-recurring set up cost of the “stencil” used to build the chip) is now at about $7 million.

The industry is meeting these challenges with improved manufacturing processes, improved CAD tools to aid in automating complex designs, and with advanced verification technologies.

TSS: In which development phase is the new Prodigy chip?

RD: TheProdigy Universal Processor chip is in the physical design stage of product development. The architecture development and optimisation is complete. The Register-Transfer-Level (i.e. Logic) design of the Prodigy core is more than 90 percent complete. The system integration of the final product is underway, with tapeout to fabrication in 2020. Early in the first half of 2020, Tachyum will release an FPGA-based fast emulation system of the full 64-core Prodigy product, which will replicate all Prodigy functionality and enable early adopters to develop and debug Prodigy software, in preparation for sampling the Prodigy Universal Processor in the final quarter of 2020.

Radoslav Danilák at 2017 GLOBSEC conference in Bratislava. (source: TASR)

Radoslav Danilák at 2017 GLOBSEC conference in Bratislava. (source: TASR)