The city of Bratislava has its first-ever bus stop created using 3D printing technology. The new stop, located on Harmincova Street in the Dúbravka borough, marks a significant step forward in innovative urban infrastructure.

Completed in early April, the bus stop is the result of a collaboration between the architectural studio Architekti Šebo Lichý and ITB Development – the investor behind the nearby Čerešne residential project – as well as the Collarch platform and Czech company ICE Industrial Services, which handled the 3D printing of the concrete components.

The architects approached the project as an opportunity to explore new technological solutions, namely 3D concrete printing.

“The project presented an opportunity for us to test a new technological approach – concrete 3D printing – which allows for the creation of complex geometries without the need for formwork,” the architects wrote on their website, adding that it also enables structural shapes to be optimised and material usage minimised in terms of both static and other requirements.

“Experimentation and innovation are always a challenge, but in this case – a public space project, and one as heavily used as a public transport stop – the stakes are even higher, which is why thorough testing was essential.”

The structure is composed of just four main elements, significantly reducing material consumption, waste, and environmental impact. The design prioritised functionality, ergonomics, and aesthetics. The striking concrete form, with its sharply defined lines and wall openings, interacts playfully with light and is illuminated in the evenings. The bus stop is also intended to be durable, long-lasting, and low-maintenance.

The project is the culmination of several years of cooperation, with ICE Industrial Services managing its realisation.

“This was the very first time we printed a five-metre-wide arch directly onto a pre-printed mould,” said architect Michal Mačuda from ICE Industrial Services. “As far as we know, this is a unique achievement – we haven’t seen anything like it done anywhere else in the world.”

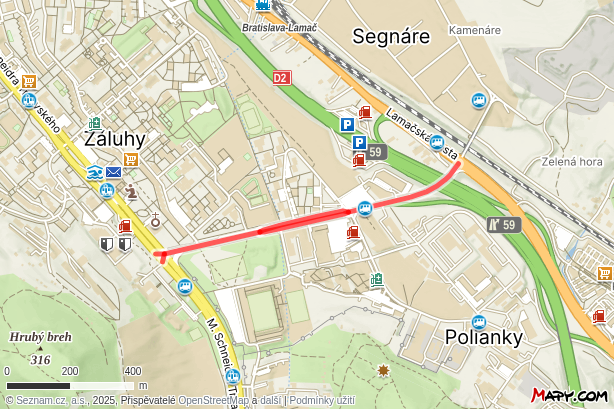

Bratislava’s first bus stop made using 3D concrete printing technology is located in the borough of Dúbravka. (source: TASR - Dano Veselský)

Bratislava’s first bus stop made using 3D concrete printing technology is located in the borough of Dúbravka. (source: TASR - Dano Veselský)