Material chemist Milan Sýkora creates materials with properties tailored exactly to suit the need of a particular application. Having spent 26 years at the US universities and institutions, he returned to Slovakia to found the Laboratory for Advanced Materials (LAM), which is part of the Faculty of Natural Sciences at Comenius University in Bratislava.

Sýkora spoke to The Slovak Spectator about the size of the nanoscale, how artisans in the past used some principles of nanotechnology without fully understanding the science behind it, how size affects the properties of materials, and the two patent applications he and his team have submitted.

Nuclear physicist Martin Venhart told me that if an atom were the size of a football stadium, the nucleus in the middle would be the size of a table tennis ball. Is there a similar way to describe the size of the nanomaterial?

Although nanomaterials are much larger than an atom-they are actually assemblies of hundreds to thousands of atoms-to describe their size we can indeed use a similar analogy. If we were to take the same example of a football stadium, we could say that you could place about as many nanoparticles on a surface of a single grain of salt as you could place grains of salt on the surface of a football stadium. When awarding Nobel prize in Chemistry in 2023, the Nobel Committee used a different comparison: if you compare the size of a nanoparticle to a football, it would be like comparing the size of a football to the size of the Earth. Yet another comparison I often tell my students is that nanoparticles are objects that are a little smaller than viruses, but a little larger than molecules. Simply put, nanomaterials are very, very small pieces of matter.

Is nanotechnology a purely modern scientific field, or have some of its principles been used in the past, even if unknowingly?

You are correct, people have been using nanomaterials unknowingly for centuries. One often cited example is the production of decorative stained coloured glass used for example in windows of churches and ancient cathedrals. Ancient glassmakers knew that when they added gold or silver salts to hot molten glass and cooled it at the right speed, the glass turned red or yellow, respectively. Another example is when ancient blacksmiths exposed hot steel to a certain type of smoke prior to hardening. They observed that this often improved the properties of the steel.

Of course, neither the glassmakers understood that the colouration of the glass was caused by small metal nanocrystals that form during the slow cooling of the glass, nor the blacksmiths understood that the properties of the steel were improved due to carbon nanoparticles incorporated into the steel. Their observations were empirical. Only in the last 30 to 40 years the field of nanoscience advanced enough that we now understand the origins of the unusual properties of nanomaterials and have the means to prepare many types of nanomaterials with various sizes and shapes in a reproducible and controlled way and effectively incorporate them into applications.

Is size the main factor in determining the properties of materials?

The properties of many materials we work with change dramatically with size and shape. One effect responsible for this observation is the ratio of the number of atoms on their surface and in their volume. Because nanomaterials are so small, that ratio is quite different than in materials we know from everyday life. Take a fist-sized rock, for example. Most of the atoms that make it up are in its volume, while a small fraction is on its surface. As you start to shrink it, its volume consists of fewer and fewer atoms, and the ratio of the numbers of surface atoms to those within its volume increases. As we get down to the nano-size the effect so dramatic that we could say that the smallest nanomaterials are mostly surface. This often dramatically changes their physical and chemical properties. For example, under normal conditions, gold melts above 1000 °C, but very small nanoparticles can melt below 100 °C. Also, while regular size gold is known as a chemically inert (noble) material, nano-size gold was shown to be a chemical catalyst.

There are other effects that change properties of nanomaterials due to their small size, and new ones are discovered all the time. Here's another example. When a standard size semiconductor material interacts with light, charged particles form that take up a volume of several nanometres. When the same material is prepared with size that is smaller than that, the charged particles are squeezed into a smaller volume than in the standard material. We say that they are spatially "confined". This dramatically changes optical, electrical, magnetic and other properties of the material.

And these properties can be tuned as the size and shape of the nanoparticle change. In other words, while common materials have properties strictly defined by their chemical composition and structure, nanomaterials with the same composition and structure can have completely different properties, which can be tuned. This has tremendous practical consequences. If we understand the laws that govern the properties of nanomaterials, we can, in principle, design materials with properties tuned optimally to the need of a specific application. This is in fact already being exploited in countless new technologies. If you were to put together a piece of metallic material made of nanoparticles next to a same-sized piece of standard material, the former would behave differently.

What is it like working with something as small as a nanoparticle?

Similar to molecules, we can't see nanoparticles with the naked eye, so we work with them in a similar way to how we work with molecules. In our laboratory we use chemical methods to prepare nanomaterials. However, the conditions are slightly different than in preparation of molecules. For example, while new molecules are typically prepared at temperatures 150 °C or less, in preparation of crystalline nanomaterials we often use temperatures of 250 °C or more. Also, the methods we use to descibre nanomaterials are slightly different. For example, in studies of nanomaterials we often use advanced microscopes, which allow us to observe individual nanoparticles. This is not commonly done with molecules, which are characterized by other methods.

Do you do this directly in the LAM, or do you just simulate the experiments?

We work with nanomaterials directly. We produce them, then we study them with microscopes and other experimental methods. When we identify nanomaterials with unusual properties, we quickly start thinking about what applications they could be used in and then we test those.

So you do both basic and applied research?

Yes. Part of the former is focused on understanding the laws that govern why and how properties of nanoparticles change due to changes in size and shape. Once we understand this, we start thinking about their application in known technologies or how they can be used for some new technology, and we try to test at least an initial prototype or the principle. It is not something that can be sold commercially right away, but we want to show that the practical potential is really there. Once we have done that, we try to find partners who can help us to commercialise it.

Have you managed to do so?

Since the LAM's inception, we have filed two European patent applications. One application concerns nanoparticles with a practical potential as contrast agents in bioimaging. What is different compared to other available materials is that our nanomaterials have a very intense luminescence in the near-infrared part of spectrum, where most biomaterials and human tissues are optically quite transparent. This means that our nanomaterials could be used in development of biological assays or even potentially as contrast agents for bioimaging of unhealthy, for example cancerous, tissues. This could make it easier for surgeons to effectively remove such tissues. Thanks to the tunability of the optical properties of nanoparticles, we were able to fine-tune their emission to the optical region optimal for these applications. Recognizing the practical potential, we filed the patent application, and we have since been approached by commercial partners.

And the other patent?

The other patent concerns materials that have been recently identified in the scientific literature as having the potential to significantly increase the efficiency of solar cells. However, the known methods for preparation of these materials are not compatible with those needed for fabrication of solar cells, as they require use of very high temperatures - above 1000 °C and use of toxic and explosive chemicals. We have found that these problems can be overcome by use of reagents that significantly reduce the amount of energy required for the reaction, thus decreasing the required temperature. This opened a path to integration of these new materials into next generation of solar cells. There has been commercial interest in our new method, and it looks like we may start a collaboration with an industrial partner to produce a proof-of-concept device prototype.

It sounds like Slovakia has something to offer in the field of nanotechnology.

Certainly. We are not the only group in Slovakia that is doing research in this area. There are many talented people and strong research groups in Slovakia. The question in my mind is how many of the clever ideas and inventions produced here will make it into practice. One thing that surprised me after we filed the patent applications was that there was relatively little interest in our inventions from Slovak companies or investors. The interest came mostly from abroad. Of course, we are pleased with this, but we would be even happier if the inventions produced here could be commercialised in Slovakia, so that added value of the technologies stayed here. It will be sad if our inventions are transformed into a finished commercial product elsewhere and Slovak customers will be eventually forced to buy it at higher cost from abroad.

You worked in America for many years. Could you tell us about your time there?

I completed my master's degree in Slovakia in 1990. The conditions for experimental sciences I was interested in were at that time very difficult in Slovakia. Therefore, shortly after completing my master’s degree I decided to apply to PhD programs in western Europe and US. The universities in the US were the fastest to reply to my applications and after some decision process I decided to join the PhD program at Marquette University in Milwaukee, Wisconsin.

My original thought was that after finishing my PhD I will return to Slovakia. However, after I did my PhD I was recommended to complete a postdoctoral training. I found a post at University of North Carolina at Chapel Hill and I managed to get into a very prestigious research team of Thomas J. Meyer. After that experience, I felt I still have a lot to learn about how to effectively do high-level science. I was able to join Los Alamos National Laboratory in New Mexico, one of the most prestigious materials research institutions in the world.

During my 16 years at Los Alamos as a Technical Staff Member I participated in and led many research projects in the area of materials and nanomaterials research. I had the opportunity to work with some of the best materials scientists in the world on some cutting-edge research. I found the experience to be very educational and productive, and I got to experience, and be part of, what was a revolutionary period in the development of nanomaterials in the early 2000s.

I'm sure you get this question a lot, but what brought you back to Slovakia?

I was in the US for 26 years in total. Whether to return after such a long time was a complex decision. There are many factors that my family and I carefully evaluated. We agreed that after 15 years in Los Alamos it was time for a change. We considered many options in US and Europe. We also reflected on my original plan to learn about science as much as I can and then bring the knowledge I had gained back to Slovakia. We eventually concluded that if I really wanted to return, it would make sense to do it before I got too close to the retirement age.

I then inquired with colleagues in Slovakia about the possibilities to return. They told me it would be difficult to set up a new laboratory, but that the European Commission provided grants that may help with such transition. I wrote a proposal for building a new research laboratory and together with the colleagues from Comenius University we applied for the funding. The proposal was successful, and gave me an opportunity to try to build a new research laboratory at Comenius University and bring back some of the knowledge I had gained in the US.

You now also teach. Did you teach in America?

Yes, I had the opportunity to teach while I was a PhD student and a researcher at universities, earlier in my career. However, at Los Alamos the opportunities for teaching were limited, as the laboratory is not directly affiliated with a university. While there, I interacted with students and postdoctoral researchers as a mentor. I trained many postdoctoral researchers and several PhD and Masters students.

If you were to compare US students with their Slovak counterparts, how would the latter fare?

General comparison is difficult because there are large variations in quality of education across the US and also Slovakia. However, I think students of elementary and secondary schools in Slovakia have access to education that can give them foundations comparable to those accessible to US students. One difference that I see is a greater emphasis in US on problem solving and less on accumulating knowledge. This is particularly true at the university level. This is slowly changing in Slovakia, but we still have a lot of room for improvement here. Motivated Slovak students certainly wouldn't be lost abroad - there are many examples of our students doing really well at top-tier international universities.

Do you have international students in your group?

Yes. In fact, majority of our group is currently made up of international students. One reason for this is that there are relatively few Slovak students interested in studies in fields relevant to the research we do, so when recruiting, besides trying to attract Slovak students, we have to extend our search for students internationally. I see a lot of positives in having an international group. International students who join our team are often coming from institutions that are ranked higher in various international rankings than Comenius University. They are usually well trained. This is a big plus for Slovak students who join our team, as this gives them an opportunity to learn from their international colleagues and experience an environment that is common at top research institutions around the world, without the need to travel abroad.

If it is the case that the universities they studied at are ranked higher, then why do they come here?

Based on some of the conversations I had with our students I believe there are two primary reasons. One reason is that they believe that the conditions for doing science in the European Union are better than in their home country. This is particularly true for the students from India, Pakistan and Iran. Another reason is that when they look at the quality of our research as reflected in our publications, they see it could help their careers to be part of our group.

This article is supported by the ESET Foundation, whose annual ESET Science Award recognises exceptional scientists.

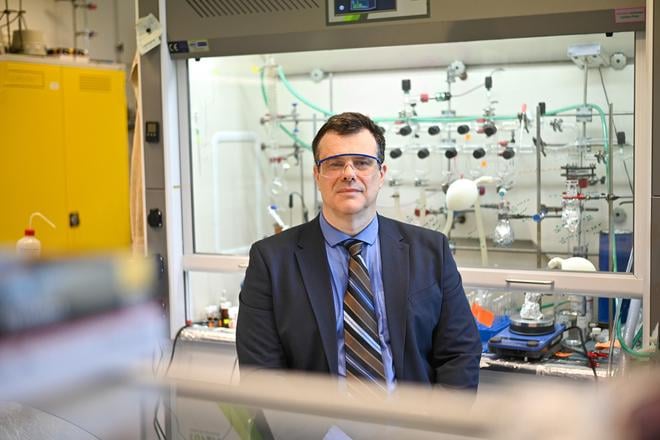

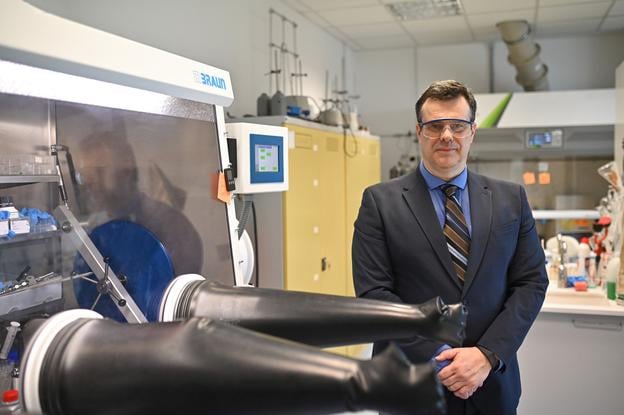

Material chemist Milan Sýkora. (source: ESET/Linda Kisková Bohušová)

Material chemist Milan Sýkora. (source: ESET/Linda Kisková Bohušová)

Material chemist Milan Sýkora. (source: ESET/Linda Kisková Bohušová)

Material chemist Milan Sýkora. (source: ESET/Linda Kisková Bohušová)